Common Names: Hastelloy C22, Nickel 22, Alloy 22, Nicrofer 5621.

Hastelloy C22 (UNS N06022, W. Nr. 2.4602, NiCr21Mo14W) is a fully austenitic advanced corrosion-resistant alloy that offers resistance to both aqueous corrosion and attack at elevated temperatures.

|

Form |

ASTM |

|

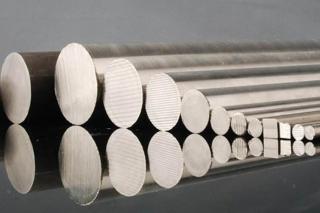

Rod |

B 574 |

|

Plate, sheet and strip |

B 575 |

|

Seamless pipe and tube |

B 622 |

|

Welded pipe |

B 619, B 775 |

|

Welded tube |

B 626, B 751 |

|

Welding fitting |

B 366 |

|

Forged or rolled pipe flange and forged fitting |

B 462 |

|

Billet and bar for reforging |

B 472 |

|

Forging |

B 564 |

|

% |

Ni |

Cr |

Mo |

Fe |

W |

Co |

C |

Mn |

Si |

P |

S |

V |

|

min |

balance |

20.0 |

12.5 |

2.0 |

2.5 |

|

|

|

|

|

|

|

|

max |

22.5 |

14.5 |

6.0 |

3.5 |

2.5 |

0.015 |

0.50 |

0.08 |

0.020 |

0.020 |

0.35 |

Physical properties

|

Density |

8.69 g/cm3 |

|

Melting range |

1325-1370℃ |

Applications: Chemical processing involving acetic acid, acetic anhydride and complex acid mixture; pickling operations; cellophane manufacture; chlorination systems; electro-galvanizing rolls, expansion bellows; flue gas scrubber systems; geothermal wells; HF furnace scrubbers; incineration scrubbers; nuclear fuel reprocessing; pesticide production; phosphoric acid production; heat exchangers; selective leaching systems; sulfur dioxide cooling towers; sulphonation systems; and weld overlay.

Note: Hastelloy and C-22 are registered trademarks of Haynes International, Inc. Inconel is a registered trademark of the Special Metals Corporation group of companies.

|

Alloy |

ASTM |

DIN |

GB |

|

|---|---|---|---|---|

|

New grades |

Old grades |

|||

|

Hastelloy C-22 |

UNS N06022 |

2.4602 |

NS3308 |

|

|

Hastelloy C-276 |

UNS N10276 |

2.4819 |

NS3304 |

NS334 |

|

Hastelloy C-4 |

UNS N06455 |

2.4610 |

|

|

|

Hastelloy C-2000 |

UNS N06200 |

2.4675 |

|

|

|

Hastelloy C-59 |

UNS N06059 |

2.4605 |

|

|

|

Hastelloy B |

UNS N10001 |

|

NS3201 |

NS321 |

|

Hastelloy B-2 |

UNS N10665 |

2.4617 |

NS3202 |

NS322 |

|

Hastelloy B-3 |

UNS N10675 |

2.4615 |

NS3203 |

|

|

Hastelloy X |

UNS N06002 |

2.4613 |

|

|

|

Hastelloy G30 |

UNS N06030 |

2.4603 |

|

|

- Nickel Based Alloys

-

Super Special Stainless

- Duplex 2205/ S31803/1.4462/F51

- Duplex 2507 / S32750 / 1.4410 /F53

- Duplex S32760 / 1.4501 / F55

- 904L / UNS N08904 / 1.4539

- 253 MA / S30815 / 1.4835

- 254 SMO / S31254 /1.4547

- 17-4PH / AISI630 / 1.4542

- AISI 316Ti / 1.4571

- 317L Stainless Steel

- AISI 310MOLN / 1.4466 Stainless Steel

- 347/347H 1.4550 Stainless Steel

- UNS N08367 / AL-6XN® / 1.4529

- Stainless Steel

- Alloy Steel