|

美标牌号 ASTM/ASME Grade |

UNS | Chemical Component % | ||||||

| Ni | Fe | Cu | C | Mn | S | Si | ||

| Nickel 200 | N 02200 Ni 99.2 | ≥99 | ≤0.04 | ≤0.25 | ≤0.15 | ≤0.35 | ≤0.01 | ≤0.35 |

| Nickel 201 | N 02201 2.4060 | ≥99 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.35 | ≤0.01 | ≤0.35 |

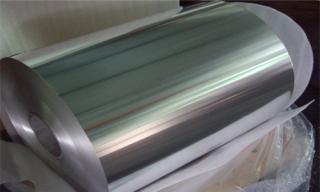

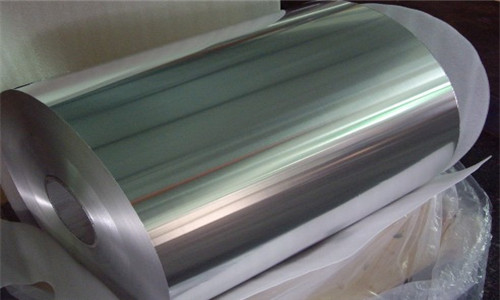

Coil Strip Thickness:

Cold rolled:0.01mm-6mm

Hot rolled: 3.0mm-14mm

Width: 5mm-2000mm

Length: as customer requirement

Packing:

Packed and labeled according to the regulations and customer's requests.Great care is taken to avoid any damage which might otherwise be caused during storage or transportation.With wide experience and expertise, Jiangsu Bealloy Co.,Ltd is one of the leading Nickel coil strip manufacturers and suppliers. We have hundreds of high-qualified workers at your service. Please rest assured to get the competitive price stainless steel coil strip with us.

| Surface finish |

Characteristics and application |

|

2B |

The surface brightness and flatness of no 2B is better than no2D. then through a special surface treatment to improve its mechanic al properties,No2B could nearly satisfy comprehensive uses. |

|

No.1 |

Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

|

No.4 |

Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

|

HL |

Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

|

BA |

Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

|

8K |

The product have excellent brightness and prefer reflexivity can to be the mirror. |

- Nickel Based Alloys

-

Super Special Stainless

- Duplex 2205/ S31803/1.4462/F51

- Duplex 2507 / S32750 / 1.4410 /F53

- Duplex S32760 / 1.4501 / F55

- 904L / UNS N08904 / 1.4539

- 253 MA / S30815 / 1.4835

- 254 SMO / S31254 /1.4547

- 17-4PH / AISI630 / 1.4542

- AISI 316Ti / 1.4571

- 317L Stainless Steel

- AISI 310MOLN / 1.4466 Stainless Steel

- 347/347H 1.4550 Stainless Steel

- UNS N08367 / AL-6XN® / 1.4529

- Stainless Steel

- Alloy Steel